Pens wrote:So, to clarify, you shoot the first coat of poly on the neck, then steel wool it, then shoot the tint and other coats?

i first strip the neck, which ever way you need to , do it, sand it , in this case, i actually had to scrape off the million coats of either nitrocellulose laquer or polyurethane that was on this neck along the sides before scoring the straight line down the sides of the neck for the binding channel because the top coat on this neck was sooo thick that when i first tried to score/cut into the sides to make my straight line, it started to CHIP away unevenly, so there was no way i would be able to leave the original laquer on this neck like my CIJ jaguar,

i actually scraped it all off with these flat squarish knives from the exacto blade set that i use for the bindings and block holes,

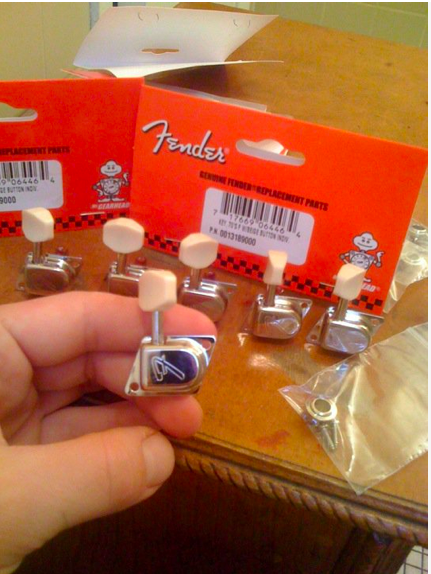

this is the set of exacto blades i get each time i do a neck, by the time i finish one neck, this entire exacto blade set is shot, all the blades either snap in half,break, get dull or chip themselves, so i need to always buy a new set for each neck, gets kinda costly

look how fuckin thick this shit was, the chips i scraped off this neck of the finish was like pieces of amber from "Jurasic park"

if you look at the picture of the blades , in the top left, the 3rd blade fom the row of blades you see, is the blade i used to scrape this entire neck, before sanding it down with 100 grit sand paper (dry), than 150 grit and finally 200 grit dry sand paper,

than with the "STEEL WOOL PADS" i use 3 different grades of the steel wool, i just go to the dollar store and get a packet of the seel wool pads, from a thicker wool to a very thin one that is very fine,

i use the very fine steel wool , i believe it is 0000 grade steel wool, the specific brand i get from the dollar store doesnt hve the grit or grade of it written on the package, it just says , thick, medium , and very fine for finishing it says,

i steel wool the hell out of it until it feel so smooth like a satin finished neck would feel,

than i spray it down with polyurethane, about 2 to 3 coats, and let dry over night, i use to just sand it down with up to 250 grit sand paper, spray with poly and than wet sand at 800 grit before staining, but this way is better, easier because if you prep the neck good enough with the steel wool , you wont have to wetsand the neck after the 2 coats of polyurethane "Before coating it with a stain,

i know it might sound "BACKWORDS">, but trust me, this is how you get the neck to stain evenly and not soak deep into the wood and make "little specs and blotches", ill post a picture below of the neck now, which is NOT Stained yet, but sitting on a wooden cabinet in my bathroom and you can see the difference in the stain, how the cabinet has little specs and darker spots and the neck is an even color, and will look the same but im gonna stain it and it will look as it is now but darker, (stained), thats how i do it

the polyurethane coats before the stain prevents the stain from actually touching the wood, therefore not soaking into it and making blotches and look like shit like the cabinet its laying on in the photo below

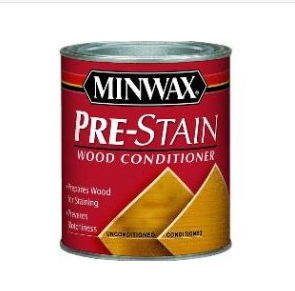

and also i forgot to mention i use Miniwax Pre Stain Wood Conditioner, just wipe it on the neck, than rub it into it, leave for a coule minutes than wipe off the excess, almost like staining it, but it just kinda seals the wood , you can get it at home epot or walmart, online, etc,.

i used to use a dark amber varnish long time ago, when i first started doing this kinda work, like 9- 10 months ago, and the varnish was so thick and dark, you woouldnt see or notice any little specs or blotches, so thats why i used to use it, but only on 2 necks until i figured this out, thank god, because those necks looked almost "Orange:" after the coats of polyurethane, because the polyurethane gives an amber tint as it is, so those necks i did in the past with the varnish looked like crap, i know, i even remember someone making fun of those 2 necks on here saying that they looked like they were "Jersey shore tanned looking necks", and that person said they would rather have the neck "Bare wood" than that ugly color, and i completely agree,, that is why i did my research and found out how to stain a neck this way.

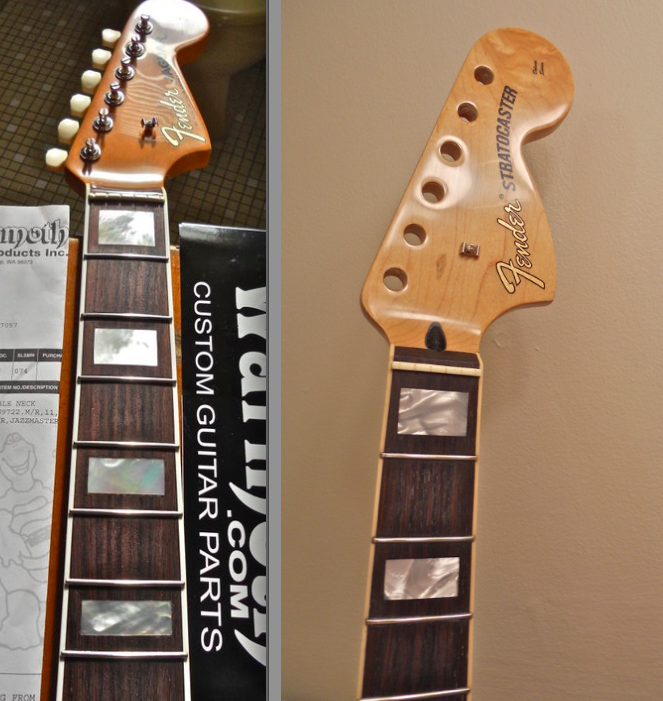

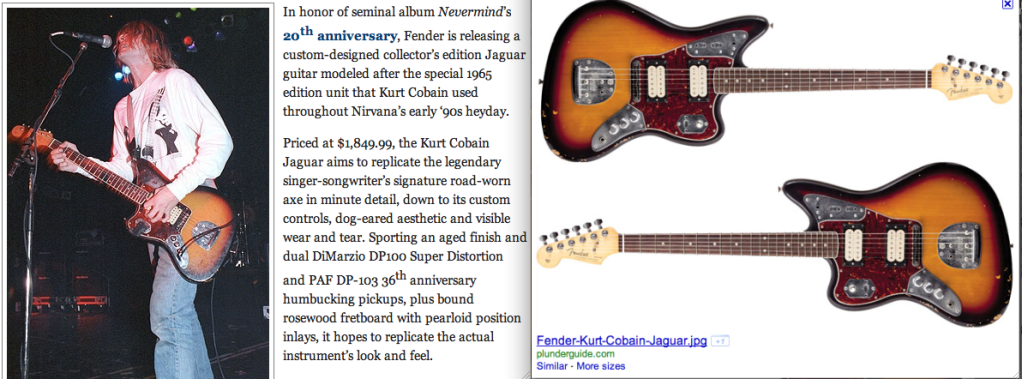

look at how dark this neck is and ugly the color, this is my first neck i ever B&B'd, the Warmoth neck i bought for my first guitar modd, that jagmaster i turned into a jaguar jazzmaster hybrid like it really shouldve been, if it wanted to live up to its name, "Jagmaster", but i learned my lesson, never make it look like this again,... ughhh

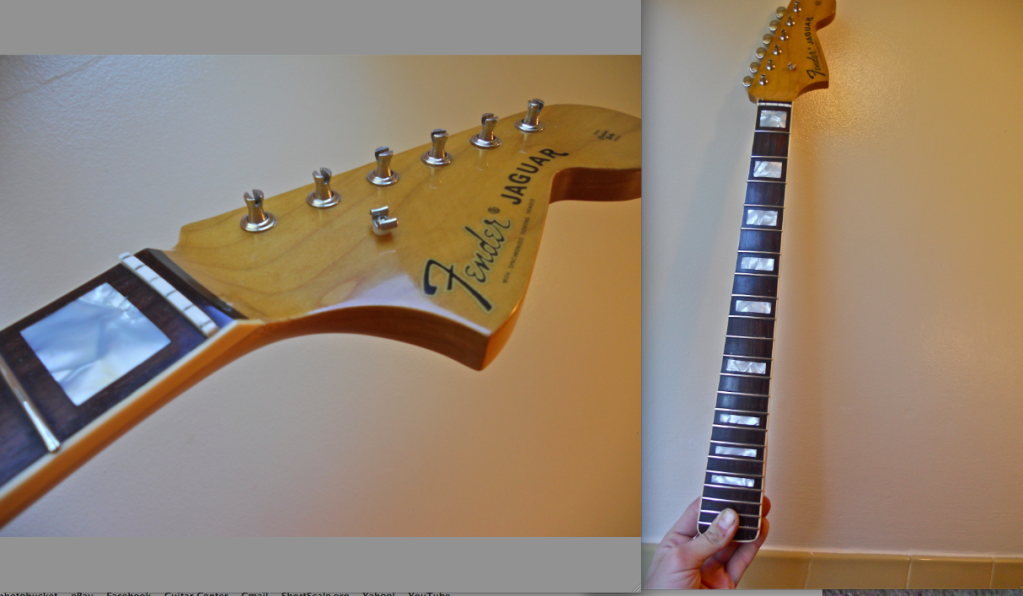

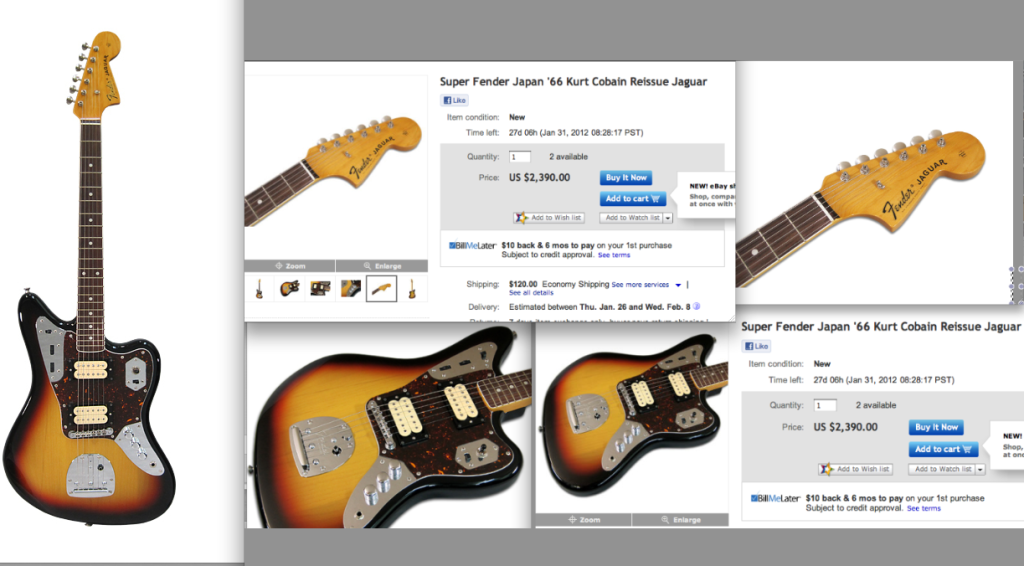

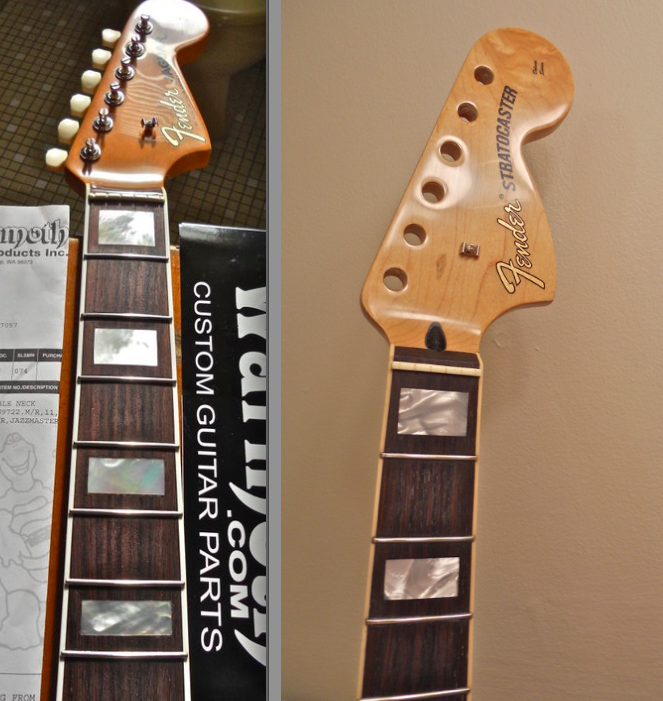

and this is how i make my necks look now, the top neck is a mex tom delong strat neck i recently did, and sold, and the bottom neck you see is another mex strat neck, tom delong, that i turned into a cbs jazzmaster B&B neck for someone, and the mij jazzmaster above mine is much darker than how i made the CBS jazzmaster neck i replaced that guys guitar with,

this was the jazzmaster i remodeled for a customer , with that CBS headstock he wanted for his brand new MIJ jazzmaster, i actually like my stain better than the MIJ neck, that looked "Orange if you ask me, atleast you cant say the neck i replaced it with was Orange,

the MIJ looked orange for sure,

here i go getting off topic sometimes or not only off topic, but talking about a million things at once , but look how even the headstock looked and how close to the vintage CBS jazzmaster neck he wanted me to replicate, although that damn truss rod hole was there, which he didnt mind, but i wouldnt keep that neck just because of the hole, i am picky with what i keep for a neck, i ,mean come on, thats really my specialty, and what i do the most, but look at the comparison of how close i got that neck to look like the vintage one on the top right in the image below

and that neck was hard because he wanted me to keep the serial number, but sand of the "Made In Mexico" part of the serial number, than i had to match the stain of the color behind the serial number, because i had to leave the numbers and color behind it, it was pretty tuff, but made it that more fun,

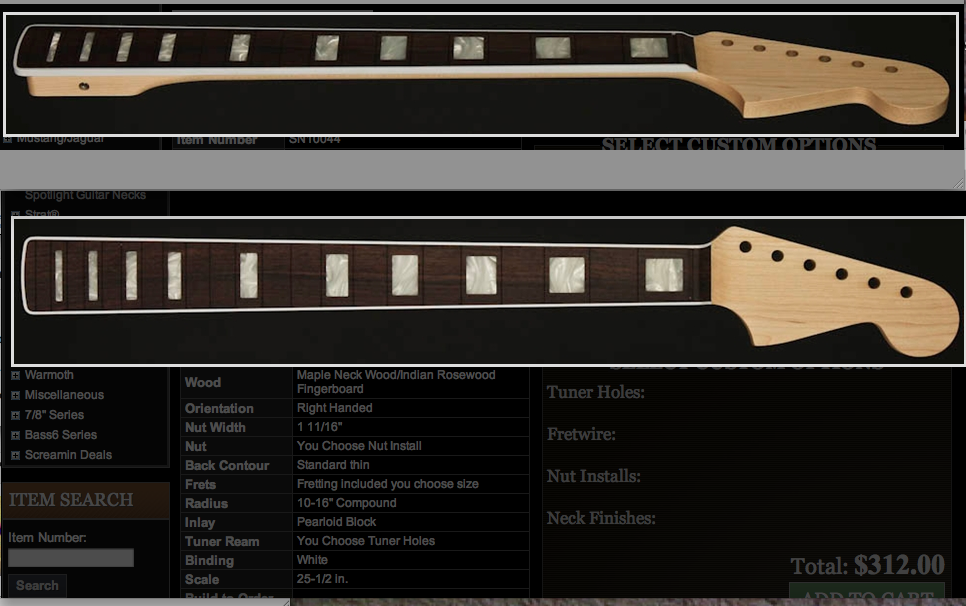

anyway, here is a shot of how my first B&B neck looked compared to a recent one which i liked alot, if i liked strats, i wouldve kept that neck on the right in the image below

the neck on the left is inlayed with "real mother of pearl block inlays, my first inlay job and i used real MOP, that was real tuff to get flush with the fretboard, i had to use a "Dremel" with the sanding/grinding drill bit, and the dust and crap that was grinding off of the pearl blocks smelled like when your at the dentist and your getting your teeth drilled, it smelled discusting, like bone, its actually a shell and was chipping if i wasnt careful,

but honestly, i like the plastic celluliod pearliod material i used in the neck on the right of the image above, i like the pattern in the blocks better than the "Real mother of pearl"

"ANYWAY" BACK TO THE TOPIC, before i get my head chopped off by these guys that hate when i post pics, let me atleast get back to this guys question, if you sand the neck down, and than use "STEEL WOOL," it will come out real nice and smooth, and than you can spray it with polyurethane, i SERIOUSLY recommend "MINIWAX polyurethane, either semi-gloss or gloss, i mostly use gloss, it self settles , not bumpy when it dries, it comes out real smooth and makes it easier to wetsand , MINIWAX is the shit, im telling you, screw nitrocellulose , that stuff is so hard, that youll be wet sanding for a week, i used it on the body of my jagmaster project, and wished i wouldve just used polyurethane, but got the job done, but litterally took me all week to wetsand and keep buffing with trutlewax to get it finally smooth , crazy, never again with nitro for me....

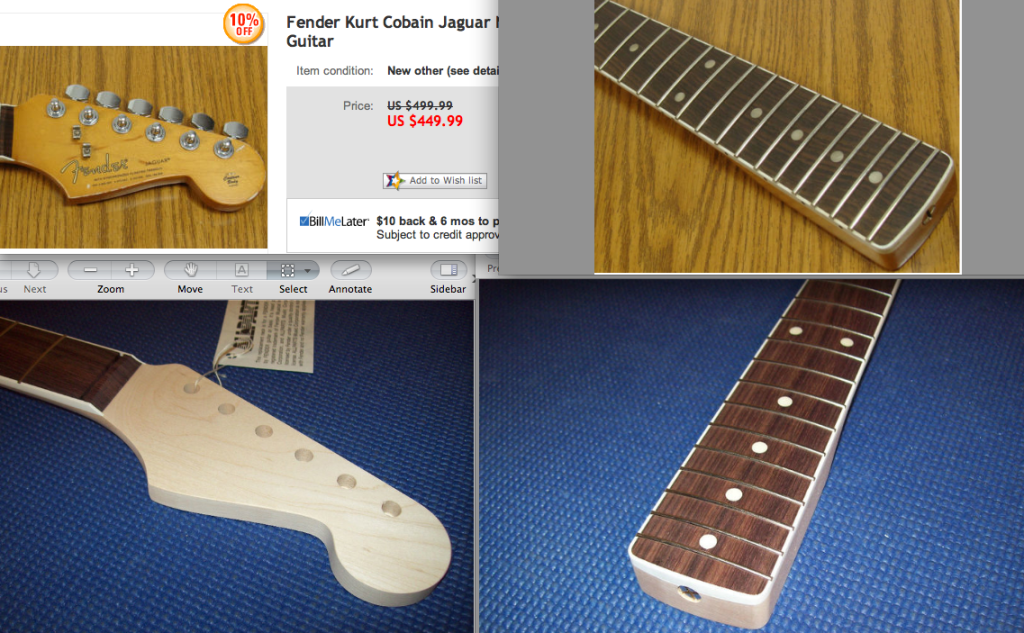

this is how the Mascis neck looked when i steel wooled it

nice and smooth

and now look at it, this is just after steel wool, pre stain wood conditioner and than i sprayed it down twice with polyurethane, AND NOT sanded after yet, or steel wool, nothing, this is it just sprayed if you prep it right, i did not wet sand yet and look how smooth it is,

another shot

and now ill leave you guys alone for a couple hours and get back to work, im doing the frets now, it is too cold out today to spray it outside and stain and spray and stain, and spray than wet sand, too cold, it could possibly fuck up the whole project, you have top time these things right and do them in the right twmperature too, sometimes its a pisser in the winter, this kind of painting sucks in the winter, unless you want you house to smell like polyurethane, im not permitted to spray anywhere in my house or garage, i go outside, hold it by the heel, spray it down outside, and quickly bring it inside to dry, and it smells up the house for a day or two, but its just something i have no control over,

this is it now, im doing the frets watching 2 and a half men, i honestly cant wait to see how its gonna look stained and with the decal, i have to do frets now though, because today is freezing, it will never dry and probably be very bumpy and bubbly if i sprayed it today and possibly fuck up the decal. so im just fretting it, taking my time, because all i need to do is finish up the fretting and decal it and finish it, probably tommorow