'Sup doods. Thanks for reading! this stuff gives me something to do when I have no life at all (I currently have no life at all).

Band sawing just outside the outline. The closer I get, the less material I have to remove with the big, scary router bit later.

This is my planer jig. It's my down draft table with a top on it, which has dowels protruding from the bottom to align it onto the downdraft table. This top also has a pair of 2" PVC pipes screwed onto it, for the sled to ride. The sled is 2 pieces of 3/4" MDF, screwed together, and it has toggle clamps to hold my router in place (in addition to a pair of 3/4" MDF guides that fit snugly around the router). The router is held very securely. I use a very large bit to plane the surface of boards, removing very little material at a time (usually 1/16" to 1/8" at a time). The dust collector sucks the blank down to the table, and it's very hard to move it. After I get one side totally flat, I flip the blank and take the other side down to the desired thickness. A jaguar is 1.625"

The majority of the material is removed from the cavities by using a 1" forstner bit. I use a 5/8" bit to hog out the smaller pickup cavities. The wire channel thing is so narrow and so shallow that I let the router bit do the work, there.

I use the world's scariest router bit to cut downhill only. I call it Satan's dong, because I'm certain that it has an evil origin, and that it wants to harm me. I hold my breath every time I use this thing.

Then I keep the guitar absolutely in the same place, but I flip the entire universe upside down, and I adjust the bit to use the opposite bearing, so that I can now cut with the grain on the areas that couldn't be cut in the last dimension.

The holes are transformed into routs by the use of a 1/2" diameter bearing guided bit. For other guitars I usually use a 3/4" bit for this, because it cuts so much cleaner, but these cavities are narrow, so 1/2" it is... I also drill the holes here.

MY neck pocket templates have dowels to fit into the bridge holes, so that I can align them instantly. They are held in place by drywall screws, which leave holes that will hide under my pickups.

Spindle sander to remove the slight wonks from Satan's dong.

Adding roundness. Should use a 7/16" but all I have is 1/2" and I actually prefer the bubblier look this way.

I carve the arm contour with a No5 Jack plane, and I do the gut cut with a band saw and then a 3" oscillating spindle sander.

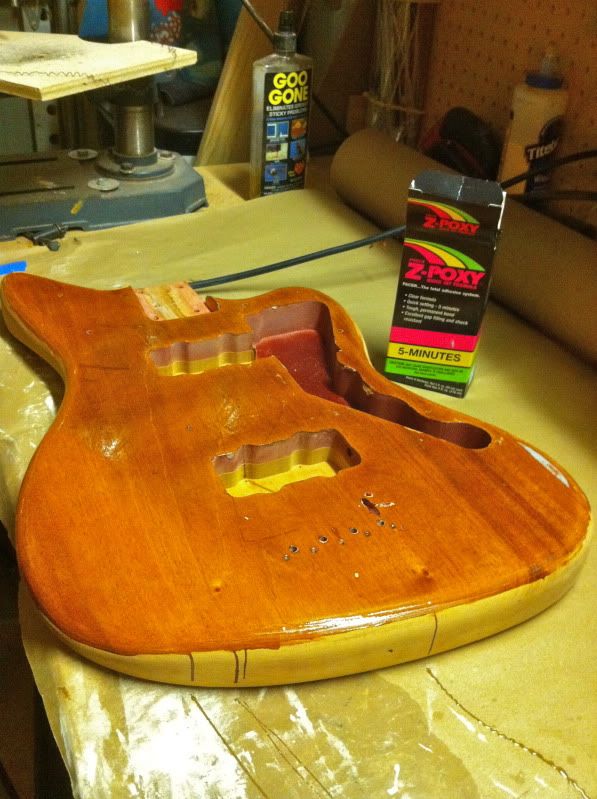

Now she just needs a good sanding, then a drippy wet coat of sealer, some more sanding, color coats, wet sand, clear coats, wet sand again, and buff.... Dang, I'm tired already.

Oh, PS: my templates are made from the templates available by Paul Rhoney, through Ponoko.com. Use your google skills and go buy some, if you are into guitar making. I'm not exactly affiliated with them, I'm just a very very pleased customer. These are EASILY the best templates I've ever gotten.